The basic process for assembling a rigid PCB begins with a polyimide dielectric film coated with extruded copper, which is less expensive than conventional copper. You then drill the cladded base material, and selective plating is applied to the plated holes to isolate the conducting layers.

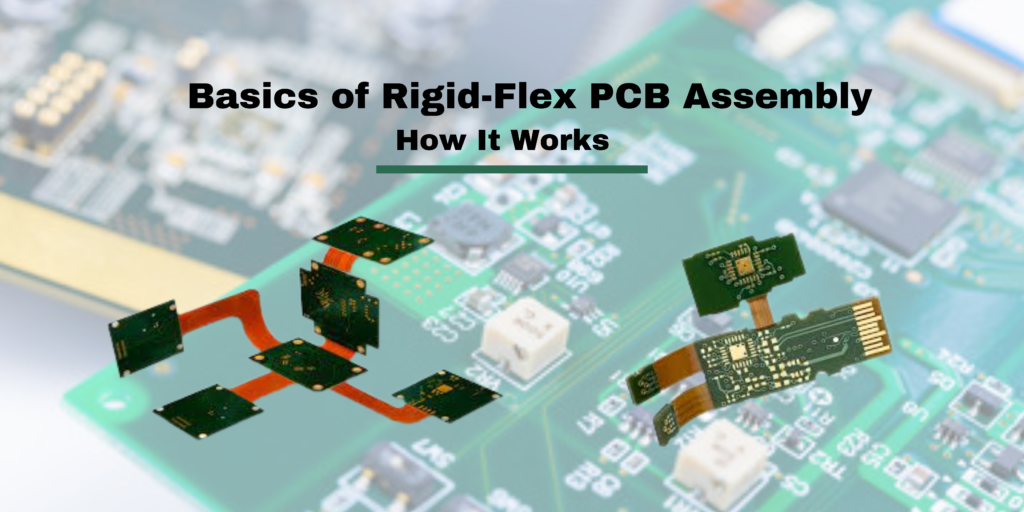

What is a Rigid-Flex PCB?

A rigid-flex PCB is a flexible circuit board with two PCB layer structure, hard core and flexible. This type of PCB has advantages over traditional PCBs in several areas, including ease of installation and packaging. Rigid-flex PCB is ideal for industrial and commercial applications to maximize space and improve reliability by eliminating specialty wires and flex cables. Rigid-flex PCBs have several advantages and excellent choice for high-reliability applications.

Types of Rigid Flexible PCBs

We categorize rigid and flexible PCB types according to the installation method. They are divided into two categories:

- Rigid-Flexible Composite PCB– You connect rigid and flexible PCBs. You will find one blind and buried between the two boards. This model will have a high density circuit design. Blind vias are those that connect two layers but do not penetrate the outer layers. Buried vias are useful for trace routing and increasing circuit space by allowing different equipment panels to connect to each other. Rigid PCBs should be designed with fewer methods and avoided by placement.

- Rigid-Flexible PCB – It manufactures rigid and flexible circuit boards separately. Then laminate them together. The through-hole design is not applicable here.

The process of manufacturing flexible rigid PCB assembly is more complex and requires more equipment and manpower. But it’s worth the extra cost because rigid-flex PCBs are great for high-end applications like TVs and medical devices.

Applications for Rigid Flex circuits

In addition to the many advantages of rigid-flexible circuits, you can make these circuits in a variety of sizes and densities. For example, polyimide circuits may have high-density ports that allow high-density circuit routing. Rigid-flex circuits also reduce overall system load. As a result, they are suitable for high shock and vibration.

Other areas include:

• Medical equipment – to detect and track breathing patterns and heart rate

• Industrial applications – such as power distribution circuits and RF equipment

• E-Commerce – Shipment Tracking and Tracking

Contact EITPL for PCB Assembly Services

PCB assembly is now more economical, more accurate and faster for automation. This enables PCB designers to obtain professional services in small and large order volumes in mass production. If you need PCB assembly services, contact one of our PCB experts.

Call us on +91 9910337896 or you can email us at info@eitpl.com and Whatsapp & Text +91 9650274009