In least difficult terms, Printed Circuit Board Assembly can be characterized as complicatedly structured pathways made by metallic inclusions for power to exchange easily, so as to achieve the segments of the electronic gadgets. This simple development of electric power encourages electronic gadgets to work easily without intrusion. Subsequent to making the printed circuit boards, the following significant advance is to amass them effectively for the fulfillment of the system.

In least difficult terms, Printed Circuit Board Assembly can be characterized as complicatedly structured pathways made by metallic inclusions for power to exchange easily, so as to achieve the segments of the electronic gadgets. This simple development of electric power encourages electronic gadgets to work easily without intrusion. Subsequent to making the printed circuit boards, the following significant advance is to amass them effectively for the fulfillment of the system.

What is printed circuit board assembly?

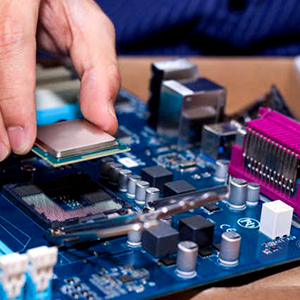

Printed circuit board assembly is the way toward interfacing the electronic segments with the wirings of printed circuit boards. The follows or conductive pathways engraved in the overlaid copper sheets of PCBs are utilized inside a non-conductive substrate so as to shape the gathering. Appending the electronic segments with the printed circuit sheets is the closing activity before utilizing the completely operational electronic gadget.

Which are the different approaches to make printed circuit board assembly?

Printed circuit board assembly is encouraged to be finished with consideration, focusing on subtleties and total exactness, as this would decide the effective activity of the electronic gadgets. The electronic machines can be in a perfect world collected with the PCBs in the 3 following ways:

Surface Mount Assembly (SMT): The method that rose during the 60s, and further created during the 80s, is presently being generally utilized by numerous PCB assembly producers. The procedure incorporates segments with metal tabs that can be effectively bound to the PCBs. The procedure offers higher circuit densities when the segments are fixed at the two sides of the PCBs with viable fastening strategies.

Plated through-gap innovation (PTH): This procedure includes parts with leads connected to them. PCBs utilized for this sort of assembling accompany boring openings. Presently, it turns out to be anything but difficult to amass the PCBs with the parts as the leads are viable embedded into the boring gaps.

Electro-mechanical assembly: Also known as box-build assembly, this strategy utilizes components like wire tackles, looms, custom metalwork, link assembly, and formed plastics so as to amass printed circuit sheets with the electronic parts.

The most up to date age is investigating the parts of microelectronics, which is driving the hardware designing and bundling industry to concoct more up to date and progressively improved advancements. Powerful and exact printed circuit board get together guarantees that the electronic gadgets work with total accuracy and profitability.

For architects looking for model printed circuit board assembly, Accelerated Assemblies is the best answer for giving administrations like Consignment Prototype Assemblies, Turnkey Prototype Assemblies, Consignment Production Assemblies, and Full Turnkey Production Assemblies.

If you have any questions about the PCB assembly, don’t hesitate to give East India Technologies a call at +91 96502 74009. and mail @ info@eitpl.com