Development is typically observed by makers as something to be thankful for – an indication of progress and a consequence of diligent work. Be that as it may, if this development isn’t gotten ready for, or the maker can’t respond in time, development can cause indistinguishable pulverizing results from if the business was in decrease.

Despite the division, fabricating all in all is a steady juggling act. It’s difficult to keep everything moving the manner in which it ought to do which is the reason you once in a while hear processing plant administrators disclose to you that running an industrial facility is ‘simple’.

Anyway, what sort of difficulties do they face when business is booming? Also, how would they conquer these weights while ensuring they keep the various plates turning? In this blog entry, we take a gander at 7 critical zones that can cause makers a cerebral pain when their business is developing alongside answers for help facilitate the agony.

Supply chain management

At the point when a client builds their ORDER book, especially without earlier cautioning, extraordinary weight can be put on the store network to keep up. This can be especially testing when bespoke or ‘drawn things’ (accuracy metalwork, plastic parts, printed circuit sheets and so forth) are included as they don’t will, in general, be held in stock in any incredible amount.

So as to control the nature of supply, makers regularly attempt and utmost the quantity of key supply accomplices they work with. Be that as it may, as requests on the production network begin to expand, issues with conveyances and sometimes quality can emerge. These issues move toward becoming elevated when the quantity of key providers the maker works with is extremely little – there’s just no place else to go.

Issues further down the inventory network not just affect the maker’s capacity to satisfy existing requests, they can likewise have a negative impact with regards to winning new business. On the off chance that a supply accomplice is as of now at the most extreme limit and attempting to adapt to existing interest, the prospect of presenting another citation for another undertaking is probably not going to be a need for them. Which, shockingly, implies the maker could then miss the solicitation for statement (RFQ) dead-line their client has mentioned.

With respect to generation arrange the board receptiveness is absolutely critical. Where possible, makers need to share their advantage measures with their supply accomplices. They additionally need to ensure they are being provided this dimension of data from their clients. Holding standard business surveys with providers to examine vacillations sought after (both all over) can help ensure that any potential interruptions to the store network are moderated. And keeping in mind that you are there it’s likewise a smart thought to detect check any stocking understandings that you have set up with the provider. It is safe to say that they are holding the dimensions of stock they focused on initially or have they been running things ‘lean’? On the off chance that they have, even the littlest increments sought after from you could significantly affect their capacity to supply.

It’s absolutely not perfect but rather if things have gone too far the assembling may need to venture in and furnish their providers with a rundown of needs so they can convey the most dire (or troublesome) things first. This is normally a final hotel activity yet it can help concentrate momentary consideration the correct way, especially if a portion of the requests that are being put are really for stock instead of firm client request.

Makers ought to likewise routinely review their providers and the abilities and limit they bring to the table. Where the holes are and what amount of a hazard do these present? Could the provider offer what you need both now and later on? If not, it’s a great opportunity to begin taking a gander at elective choices before the choice is removing from your hands.

Internal capacity

This can be an issue for producers when interest for one specific administration offering or ‘ability’ abruptly builds, stripping out interior assets. Machine developers, for instance, depend on having exceptionally gifted time-served board wiring staff set up. Be that as it may, if interest for this asset all of a sudden increments without earlier notice, the maker will battle to enroll the correct kind of work they need in time. Frequently this powers producers to enlist in transitory work through authority organizations to satisfy contracts. Not exclusively is this a costly arrangement, finding profoundly talented time served staff is incredibly troublesome in the present atmosphere and can require some investment.

Once more, close correspondence with the end client and forward arranging dependent on estimate data can help. On the off chance that the client can’t hold up the reexamined lead-time because of their expansion sought after and the maker needs to depend on momentary outer work, a talk between the two gatherings about the extra expenses brought about should happen.

Investing in new equipment

Creation gear and tooling can be costly so choices on what to put resources into and when need cautious thought. Makers will be continually surveying which hardware they need so as to keep up their own profitability levels yet in addition what gear they will require later on to fulfill the developing needs of their clients.

Holding ordinary innovation audit gatherings can be a helpful method for seeing increasingly about the end clients’ technique and how this may affect new items later on. Picking up this dimension of knowledge isn’t simple, especially if there are worries by the client around Intellectual Property, however in the event that makers can separate this data from their clients it very well may be incredibly helpful while thinking about the future venture.

Talent development

Floor space

Producers that re-appropriate components of their activity can free up immense measures of room. Being actually clear on center exercises and after that executing demonstrated techniques, for example, redistributing permits producers additional time and floor space to concentrate on the pieces of their business that tally. Amusingly, for some Original Equipment Manufacturers (OEMs), the physical procedure of structure, testing and transporting items aren’t generally center exercises at all when you contrast them with item configuration, advertising, and deals. So what are your center exercises? Also, what amount of processing plant space would you need if you somehow managed to concentrate 100% on them?

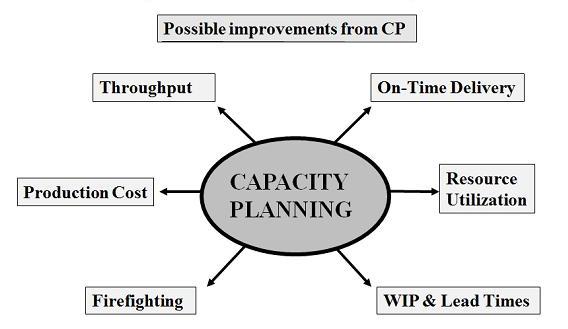

Capacity planning

Makers are regularly expected to have the capacity to ‘flex’ their ability with clients request. For a few, with changed item ranges and client bases that are various, when one item or client is ‘up’, commonly, another will be ‘down’ which mellows the blow. Makers additionally will in general work with their clients over a scope of various obtaining understandings. For instance, a few requests they get will be fixed and firm to a concurred calendar giving long haul perceivability. Others, be that as it may, may be founded on an administration level understanding (SLA) whereby item is ‘canceled’ on short notice as it is required.

Arranging can turn into a test for makers when they don’t have forward perceivability of the client request. Furthermore, ‘earnest’ client requests or potentially amendment changes must be bolstered which implies it is a steady juggling represent them to oversee. It’s essential that the business/client administration group have normal business audit gatherings with the client so as to give as much forward perceivability as they can to the arranging group. It’s additionally essential that the arranging group don’t submit the majority of their assets at some random stage so as to hold the capacity to ‘flex’ when obscure interest presents itself.

New opportunities

As the maker develops it’s vital that the business groups balance accepting on open doors from existing clients just as spic and span ones. A decent beginning inquiry for the group to ask when given any new open doors is ‘the reason us and why now’? With a limited measure of statement asset accessible it’s essential the maker focusses their consideration in the correct territories and so as to do as such, they should be sure about what a ‘perfect’ client looks like and what a ‘decent’ bit of business truly is. Making client persona or profile records can truly enable the business group to imagine this which thusly can enable them to qualify (in or out) new open doors rapidly. What’s more, in the event that they battle to characterize what a perfect client may resemble, ask them to record every one of the purposes behind what valid reason they wouldn’t exchange with somebody and after that transform every one of the negatives into a positive!

So no, running an assembling office isn’t ‘simple’. OEMs once in a while recognize what is coming to their route and thus they have to continually audit what their business needs are today just as what they will look like later on. Fortunately, insightful OEMs free themselves up from a significant part of the weight associated with assembling and re-appropriate all the non-center exercises of their business to Electronics Manufacturing Services suppliers. This abandons them to concentrate on what they are great at so they can appreciate their rewards for all the hard work and development, instead of stressing over how it could get them out.