Quality be accorded top priority to ensure cost effective and Timely supply to our customers delight.

We achieve this by total involvement of our people, Continual Improvement and Innovations.

Company certified for ISO 9001:2008, ISO 14001, ISO 13485, TS16949, Our quality objectives are driven through overall operational excellence. We act courageously in pursuit of process quality distinction.. We make the company to deliver the performance with integrity, respect and quality.

The needs of our customer’s determine everything we do at quality function. We believe that customer satisfaction is the largest single factor in driving our customer loyalty, market share and overall business success. As a market leader in electronics manufacturing, we offer consistent, new and better approaches based on customer needs. We use internal operational metrics, external benchmarking and customer feedback to measure our operational excellence.

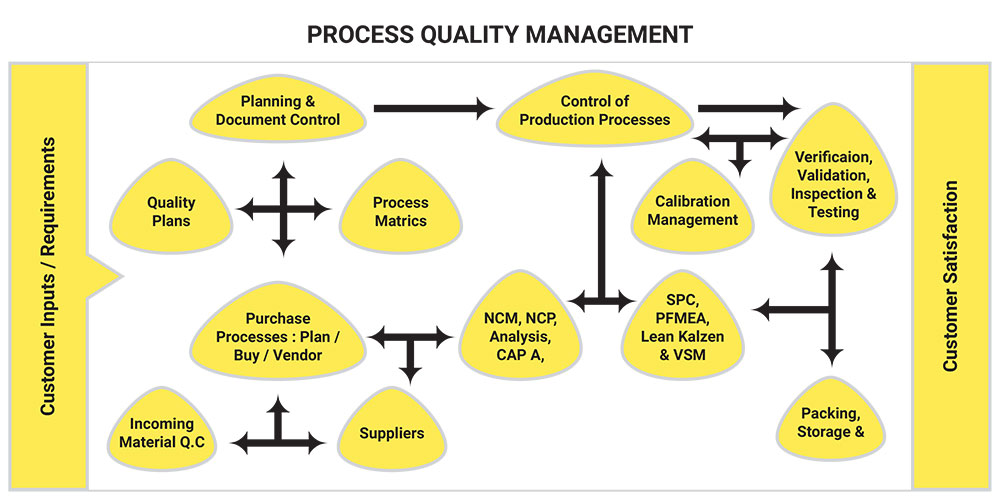

We realize that simply ensuring product quality is not good enough to differentiate a company in the EMS industry. We need to exceed customer expectations with highest quality levels. We achieve quality through:

- Impeccable quality management system to assure the quality of our products and services

- Strict Compliance to systems and continuous integration of best practices in complete span of Operations and imprint creativity as the way of our work culture

Continuous improvement is a hallmark in our day to day endeavors. We provide value to our customers and empower our employees to innovate. Our culture of continuous improvement enables us to maintain our technology leadership with a focus on superior customer satisfaction.